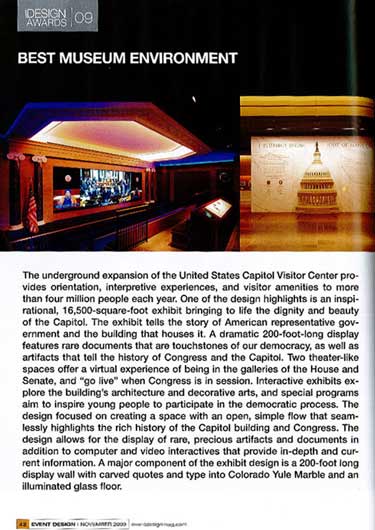

United States Capitol Visitor Center – Days 1-6

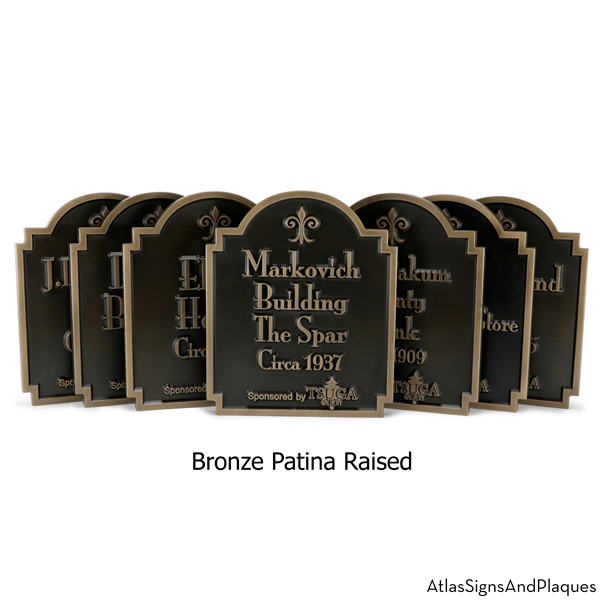

Project Overview Metal Facades (now Atlas Signs and Plaques) was contacted in December 2008 by the prestigious firm, Hadley Exhibits, of Buffalo New York and asked to bid on an exciting project using the LuminOre® metalizing process. The project turned out to be two rectangular frames 16 x 23 feet that Hadley was constructing from High-Density Polyurethane Foam (HDU). The same material that is the favorite of Atlas Signs and Plaques for custom handcrafted signs and plaques. Outer Frame, Unpacked and Ready for the Transformation The frame, quite massive, about 9 x 9 x 9 inches, and required metal coating on three of the four sides. Nestled within the foam frame is a smaller aluminum inner sub-frame meant to house 6 flat screen tv monitors and a large clock. This framework is about 17 feet long and 28 inches tall. Again, 2 of these. The plan is to [...]