No Soliciting Signs, Address Plaques, MIA and Military, Man Cave, Privacy and Message Signs Custom Made at Atlas Signs and Plaques

The signs and plaques that we create are not castings from a dirty polluting foundry.

Our signs and plaques have a base of modern High Density Urethane (HDU) board. This is a product that was developed for the aerospace industry and has been used for signage for over 40 years.

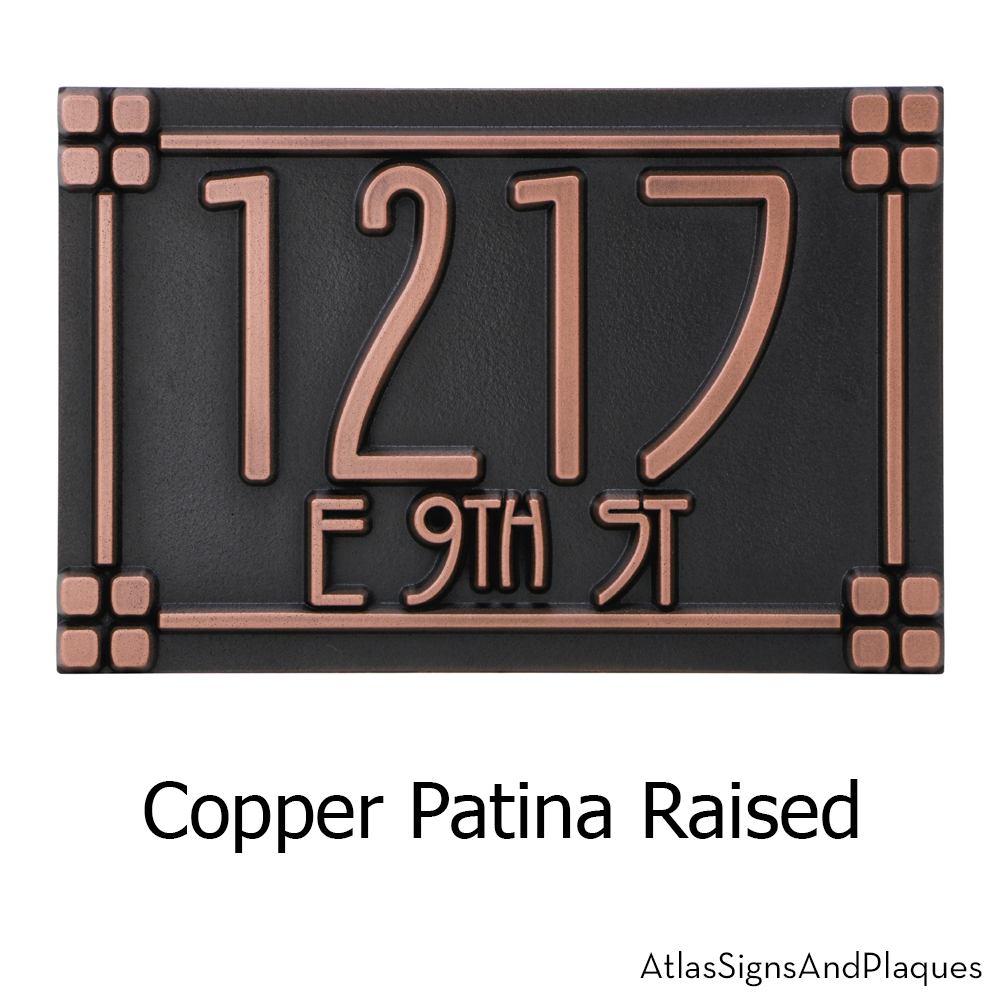

We coat our HDU signs and plaques with a cold applied, real metal coating that is in use world-wide as an architectural and industrial coating. It is a well-proven, tough, and beautiful coating that gives the look of cast metal without the limitations. Read our blog post about the metal coating we use.

Our signs and plaques are very durable, but will not stand up to repeated abuse. If you wish to embed a plaque in the ground, hit it with a mower, or look at it in 500 years, you should order a foundry-cast plaque. We are happy to supply these, but expect to pay 4-5 times as much as the affordable plaques we create using our proven methods.

When you receive your order, you will notice that it is light weight. Since it is HDU with a thin metal coating, it is light and easy to hang on any wall without fear of testing the building’s structural integrity.

We have our work outside, at the U.S. Coast Guard Academy and at locations all over the world. You will even see our accomplishments at the United States Capitol Visitor Center in Washington which has metal coated HDU in highly visible locations. The same process and materials that we employ are extensively used at the MGM Grand, Bellagio and other Las Vegas Properties. In addition to Las Vegas, this patented process in in use from Mexico to Times Square.

In fact, you have probably observed metal coated HDU, but were unaware that you weren’t looking at a foundry casting. Bottom line is architects and designers realize this as a well tested, and well accepted process, and use it without hesitation at some of the worlds most prestigious properties.

Now for the technical stuff:

Our Metal Coating. We utilize LuminOre® exclusively.

- Leach Rate Test Data: 1020 parts per billion

- Weatherometer Test: astm D2565 Completed 3000 hours without any delaminating, corrosion, blistering or breakdown.

- Envirotest Machine: astm D2246 Completed 3000 hours without any delaminating, corrosion, blistering or breakdown.

- Pull Off Strength using Portable Adhesion Tester Type II with a 0-2000 psi scale: astm D4541-95: No coating to substrate failures were reported.

Our HDU Board is from Precision Board HDU. The following is from their website:

Precision Board, being a closed cell product, absorbs no moisture. It is a fairly good insulator so temperature does not migrate into it. It has been tested from -423°F to +300°F with no degradation or breakdown. It doesn’t absorb water from high humidity, rain, snow, or ice so it does not expand or contract because of water intrusion. This means it doesn’t warp or crack and the paint lasts longer and stays brighter than on wood.

With a signs and plaques from Atlas, you will receive a quality product with the look and many of the characteristics of a foundry cast piece. You will have a truly custom product that is Made In the USA using American materials and labor. You will receive exceptional customer care from the very owners and craftspersons that are creating your selection. We want you to be thrilled with your purchase!

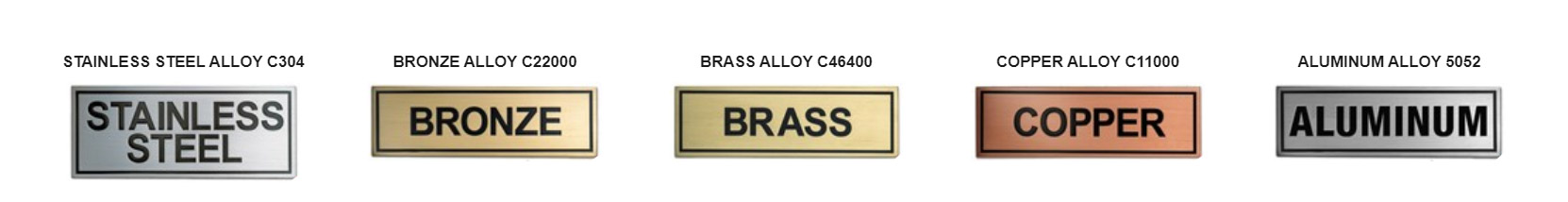

Materials We Use

The real metal coatings – Manufactured by LuminOre® and have been proven for over 20 years. These are cold-applied (meaning they wont melt things) REAL METAL coatings that allows a layer of metal to be applied over almost any substrate (surface), in virtually any configuration or design. The incredible results look, feel and act just like hot foundry cast metal but without the weight and expense. Suitable substrates include, but not limited to: laminate, melamine, wood, plastic, gypsum, fiberglass, ceramics, concrete, foam, porcelain, glass and metal.

The metal coating is not paint. It is a patented cold sprayable metalizing process comprised of up to 75% real metal. There is documented ASTM testing with zero breakdown equivalent to 30 years outside. The metal is unaffected by UV exposure, rain, sleet and snow. If left without a clear coat it will tarnish like real metal.

The clearcoats – There are a variety of clearcoats depending on the application. They range from automotive clears, ceramic resin with anti-graffiti properties, to lacquer based. We clear coat all of our signs unless requested otherwise.

The substrate (base material) of our signs – Atlas Signs and Plaques uses 18 to 30 pound – High Density Precision Board (HDU). (Density are available from 10# to 40#) HDU has been in use for over 50 years and was originally designed for insulation in aircraft. It is currently used for insulation of homes, model making, boat building and more specifically in the sign making industry.

The HDU Board is becoming a replacement for the more traditional cedar signs that would be carved or blasted with abrasives. However, the sign board will not split or warp, has no water absorption, so it won’t rot, meaning no insect attacks, and the artistic advantages are limitless.

Enamels – The enamels are the premiere enamels used in sign making for over 50 years. They are for interior and exterior uses.