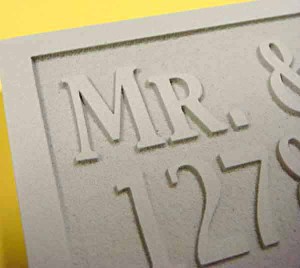

HDU Foam Ready for the Finish

The Finish Completes the Project

High-Density Urethane (HDU) and High-Density Polyurethane (HDP) (different names for the same basic product) is a wonderful material for hand carving, shaping, and machining. Having a closed cell structure, an even consistency and no grain make it a dream to work with whether making prototypes for casting, or toys for the grandchildren. It cuts effortlessly with all kinds of saws and rotary tools, and, because it is without grain, is much safer than wood for hand carving.

When completed, HDU foam is easily finished with readily available paints, stains, and dyes making it highly desirable as a medium for the craft person or hobbyist. It is utilized extensively in the sign industry because it is easily worked, environmentally friendly, non-toxic, and impervious to rot, petroleum, water, and insects. Because it does not expand or absorb water, both your work and the applied finish can last far longer than on wood. You can read more about HDU foam on our blog posting: What Is HDU? And Why Is It Used For Signs?

Assuming your masterpiece is now shaped, here is some detailed finishing information, edited from one of the manufacturers of HDU Foam. Our thanks to Sign Arts Products Corporation for making this information available.

When finishing, you must realize that this is not an organic material and you do not have to treat as such. Nothing can soak through the surface to the interior of the material. As a consequence you no longer have to think about primer and paint as a protective measure.

Priming and painting are simply a matter of aesthetics. Since no primer is needed to protect the material from the environment, applying paint without priming is becoming more and more popular. You may use any type of paint. Water based, oil based, and even lacquer-based paints will adhere well without attacking the material chemically.

A majority of your projects will require a semi-smooth or smooth surface for aesthetic reasons. The smoothing out of the surface is the only function of the primer. When priming, keep the cell structure in mind. The surface of is like the surface of an egg carton, a series of open cells. This texture cannot be sanded out. Once you have removed all machining marks with 220 grit wet & dry sandpaper, you will have sanded the material to the smoothest surface possible. Further sanding will only open the next layer of cells, revealing the identical surface texture. This surface, which might resemble painted sandpaper, may not be appropriate for your projects. Although for projects where the surface texture will not be visually scrutinized, this may be an acceptable painting method.

You can achieve a smooth finish by priming or using multiple coats. We suggest experimenting to achieve your desired final finish. Consider using the back, or apply finish before starting to an area that will be removed during the shaping process. Remember, this is a closed cell product that does not transfer or absorb liquid. Paint or coatings will not dry from below so be certain that one coat is completely dry before proceeding.

Automotive paints work very well, as do most oil or water based enamels. Any filling of voids or dings should only be repaired after at least one coat of primer has been applied. Although exterior spackle can be used for holes in areas that will be painted, use an automotive 2-part filler containing glass bubbles if you have to fill or rebuild a corner or edge. It will finish very close to the texture of the foam.

The finishing material is up to you, with a shiny finish obtained by using enamel over primer, while a mat, rustic appearance will result from the use of latex or house paint. One very important caution with latex or any water based paint! Remember that the foam is a closed cell and does not absorb liquid? That means the paint will not dry from below, and even if it seems dry to the touch, adding an extra coat will forever lock-in the wet first coat! Allowing a few days between coats is not too long. Avoid trying to hurry the drying process with heat or sunlight as the top surface will dry and lock in the water below. You might not be aware of the substandard paint job until the paint has failed in an exterior environment.

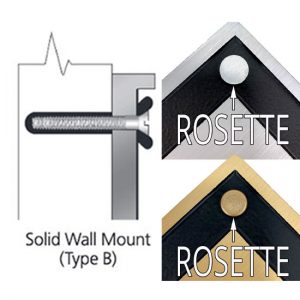

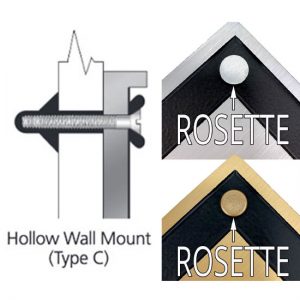

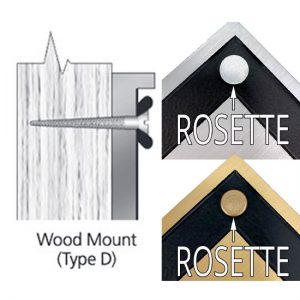

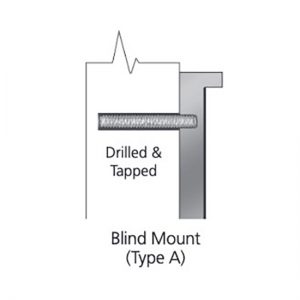

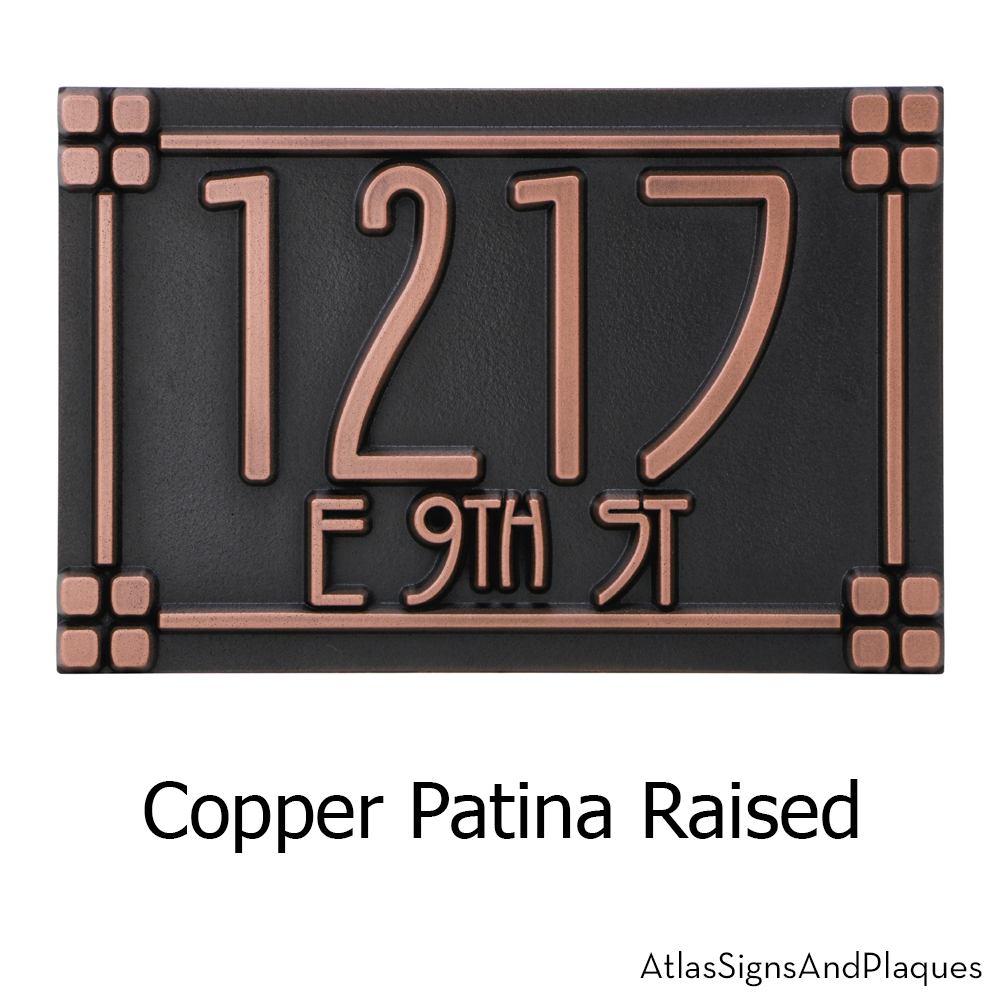

How to Mount Keyhole Hangers

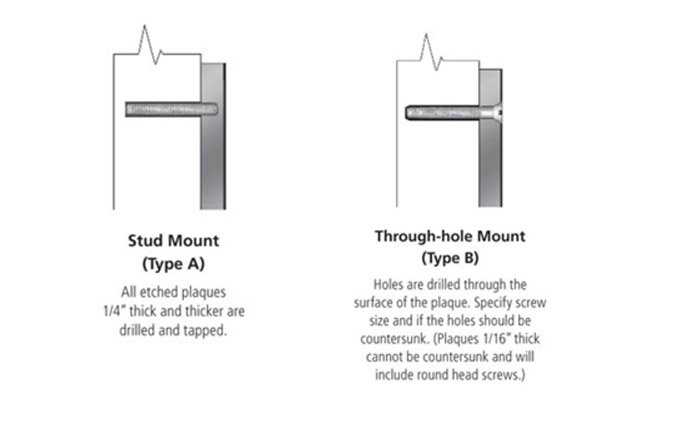

Installing mounting hardware is easy. One inch thick, eighteen pound density HDU foam weighs approximately 1.5 pounds per square foot in it’s raw state. The light weight is one of the reasons why it is used on so many projects in lue of bronze or other cast metals. (See our blog postings on the Capitol Vistitor Center) If your project requires wall hanging, you may treat it like wood with a few precautions. HDU holds common screws quite well, but in our experience, not as good as wood. Wood has a grain structure that compresses when fasteners are introduced, but HDU does not. It is not necessary to drill a pilot hole for small screws. You should drill a smaller pilot hole for larger screws than you would for wood. Don’t over-tighten screws or they will strip forcing you to place a sliver of wood or HDU in the hole and reset the screw. Nails don’t work very well, but could be successfully used to attach sawtooth type picture hangers. It is suggested that nails be driven at an angle rather than straight in to enhance holding power.

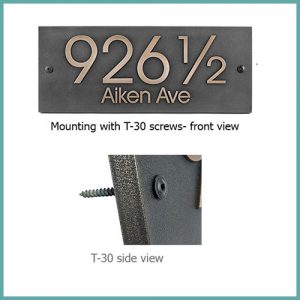

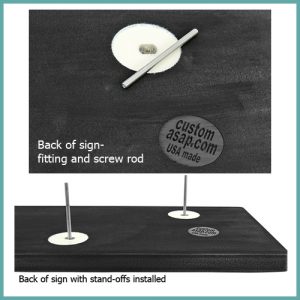

We use keyhole hangers on most signs from Atlas Signs and Plaques. They are readily available from woodcraft supply stores in one or two hole models, but finding the ones that are Made in the USA can be time consuming. We inlet them flush into the back of signs (see the demonstration photo above) rather than just attaching to the surface. Precision inletting spreads the load, allowing the HDU surface to share the shear load with the screws. You can also enhance the holding power by using some epoxy when setting screws and fasteners.

Eye screws can be inserted into HDU for items that are designed to hang. Use the longest thread surface possible if your project is heavy or subject to exterior wind. Pre-drill the smallest hole that will not distort the surface when the screw is inserted. Experiment on a piece of scrap before risking your work.

HDU / HDP is product well suited for projects ranging from home decor to large architectural projects. It is strong, light weight, easily shaped, non toxic, and very easily finished with a few precautions.