Sign Materials

We offer several different types of materials for our standard semi-custom signs in our product library: metal coated HDU board and cast metal.

Etched metal signs are available as a custom quote only.

METAL COATED HDU SIGNS

Lightweight and economical. Coated with real metal and made out of a type of “plastic” (30 pound HDU) that doesn’t warp, rot and is unaffected by weather, so outside is just fine. The metal coating is REAL metal (NOT paint) and chemically bonded to the “ plastic” and won’t flake or peel. Use for interior or exterior.

Metal Coated HDU vs. Precision/Cast Metal Signs

Metal Coated HDU Signs

- Economical

- Metal Coated

- Lightweight

- No Design Limitations

- Indoor or Exterior

- Eco Friendly

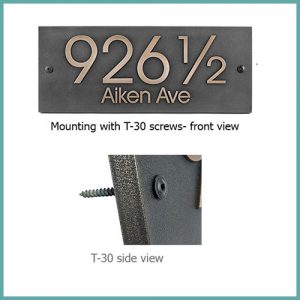

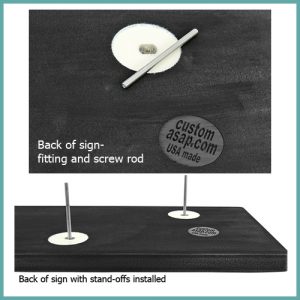

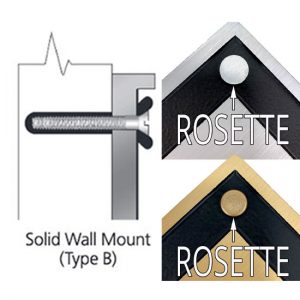

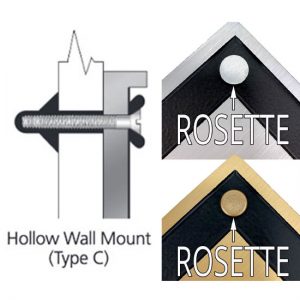

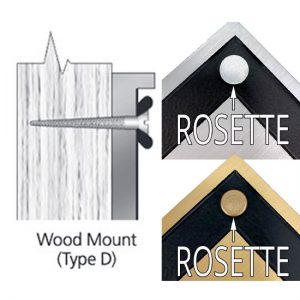

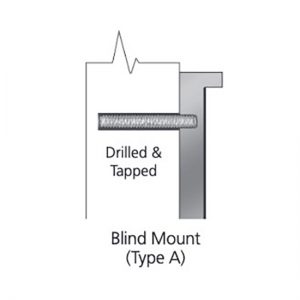

- 7 Mounting Options

- 7 Finish Options

- Hand Made

- Made in USA

- Available on Standard Signs

Precision/Cast Solid Metal Signs

- 1.5 – 2x Cost of HDU

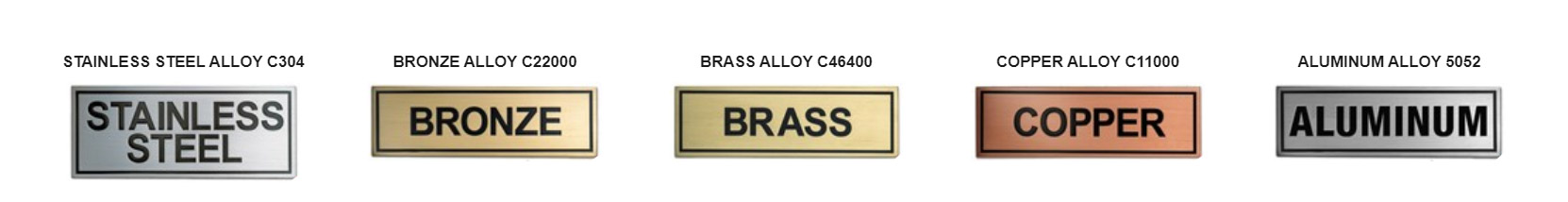

- Solid Metal

- Heavy

- Some Design Limitations

- Indoor or Exterior

- Recyclable

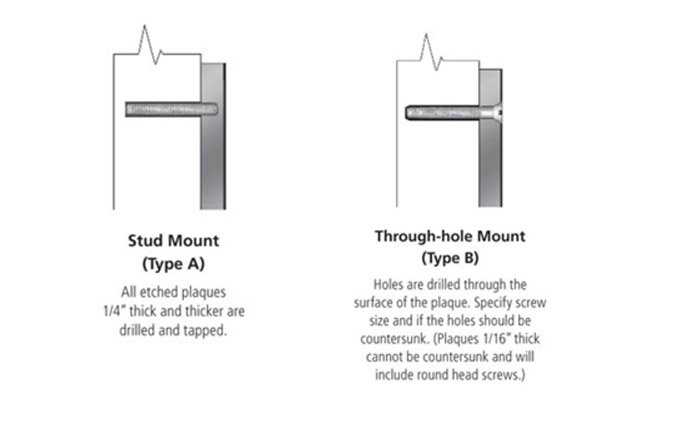

- 5+ Mounting Options

- 2 Finish Options

- Foundry Made

- Made in USA

- Available on Standard Signs