Project Overview

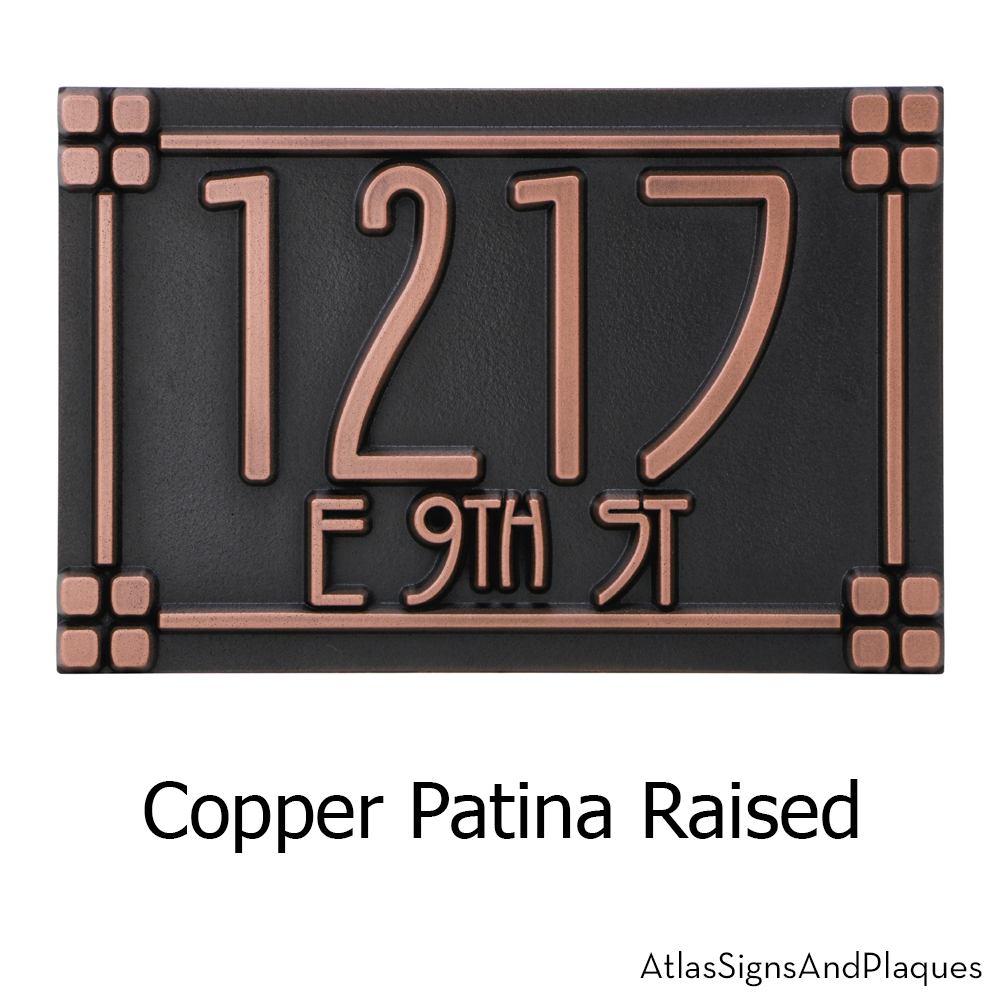

Metal Facades (now Atlas Signs and Plaques) was contacted in December 2008 by the prestigious firm, Hadley Exhibits, of Buffalo New York and asked to bid on an exciting project using the LuminOre® metalizing process. The project turned out to be two rectangular frames 16 x 23 feet that Hadley was constructing from High-Density Polyurethane Foam (HDU). The same material that is the favorite of Atlas Signs and Plaques for custom handcrafted signs and plaques.

Outer Frame, Unpacked and Ready for the Transformation

The frame, quite massive, about 9 x 9 x 9 inches, and required metal coating on three of the four sides. Nestled within the foam frame is a smaller aluminum inner sub-frame meant to house 6 flat screen tv monitors and a large clock. This framework is about 17 feet long and 28 inches tall. Again, 2 of these.

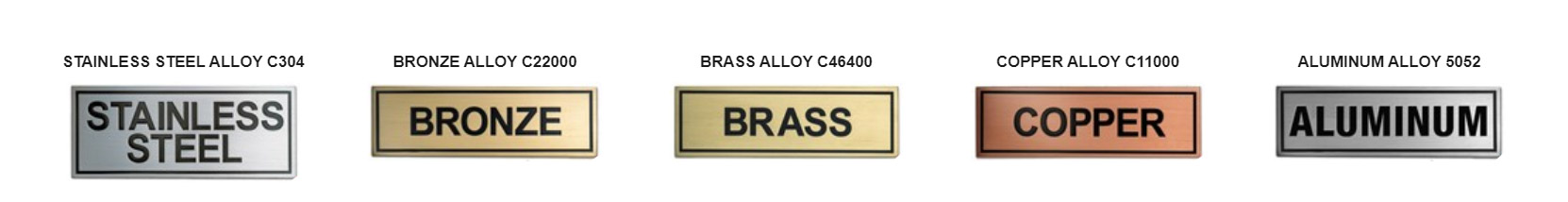

The plan is to use LuminOre® Bronze, patina, and the expertise of the Metal Facades’ (now Atlas Signs and Plaques) craftpersons, to transform both the large foam outer frame, and the smaller aluminum inner frame into beautiful Bronze without the weight or expense of foundry cast.

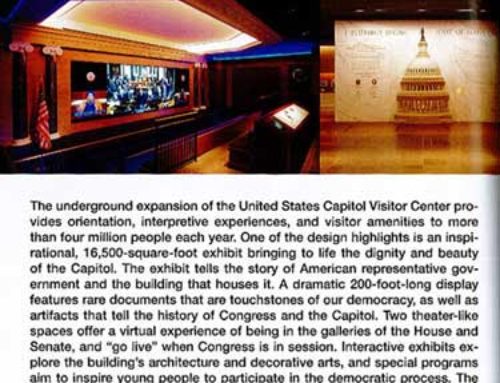

Best of all, both the inner and the outer frame are slated to go in the brand new, 580,000 square feet, US Capitol Visitor Center in Washington D.C.

Preparation and Metalizing

Day 1: Friday January 16th, 2009. Coldest day of the year in Lake Mills Wisconsin. FedEx Ground truck arrives with 3 large crates, totaling 2000 pounds, on board at 1 p.m. with the temp reading a balmy -15 F. When repeated attempts to start the forklift failed, plan B was launched. Freight stayed on board and was delivered to the FedEx warehouse in Madison Wisconsin. We rented a truck, drove to Madison, had FedEx use their forklift to lift one of the crates onto the smaller truck. We drove the smaller truck to the shop, opened the crate, hand unloaded the foam pieces, and pulled the (now empty) crate off. The same procedure was repeated to get the second and third crate.

Finally offloaded into the shop so work can begin. First to organize so each step can be completed, and work can progress in an orderly fashion.

HDU foam usually requires several coats of primer to provide a smoother surface for metalizing. The frame structure is built-up from multiple pieces of foam screwed and glued together. Of course, not all of the screw heads could be hidden, which left hundreds of holes to fill with Bondo.

Spraying Primer

Days 2-4: So…the process is prime, fill, sand, fill, sand, prime, fill, sand. And all of this just to prepare the surface. And all of this by hand, with air and electric orbital sanders the only power tools used.

Days 5-6: Preparation work nearing completion and time to spray Bronze. LuminOre® is mixed and sprayed by the gram, and a full spray gun can hold about 2800 grams. Of course, this will have to be repeated about 15 times to only complete the foam outer frame.

US Capitol Visitor Center Foam Frame

Two full days of moving the pieces, some of which are twelve feet long into the spray booth, coating them, and moving them out for the curing process while getting new pieces in and sprayed. As a note, LuminOre® is a catalyzed process and the applicator only has about 30 minutes to spray out the gun contents and start cleaning a very expensive spray gun.