United States Capitol Visitor Center – Days 7-10

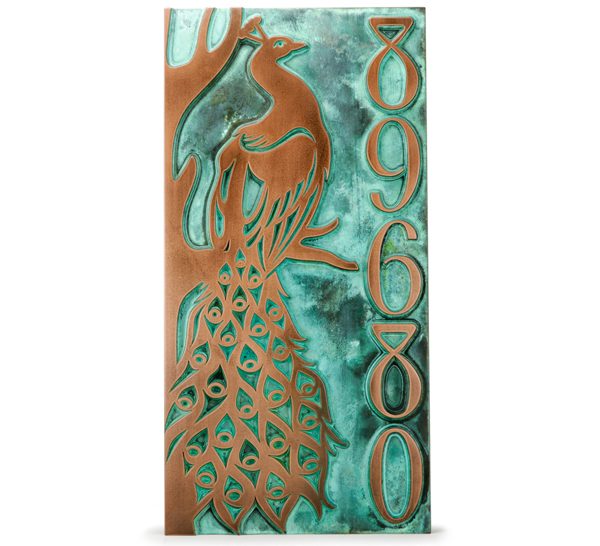

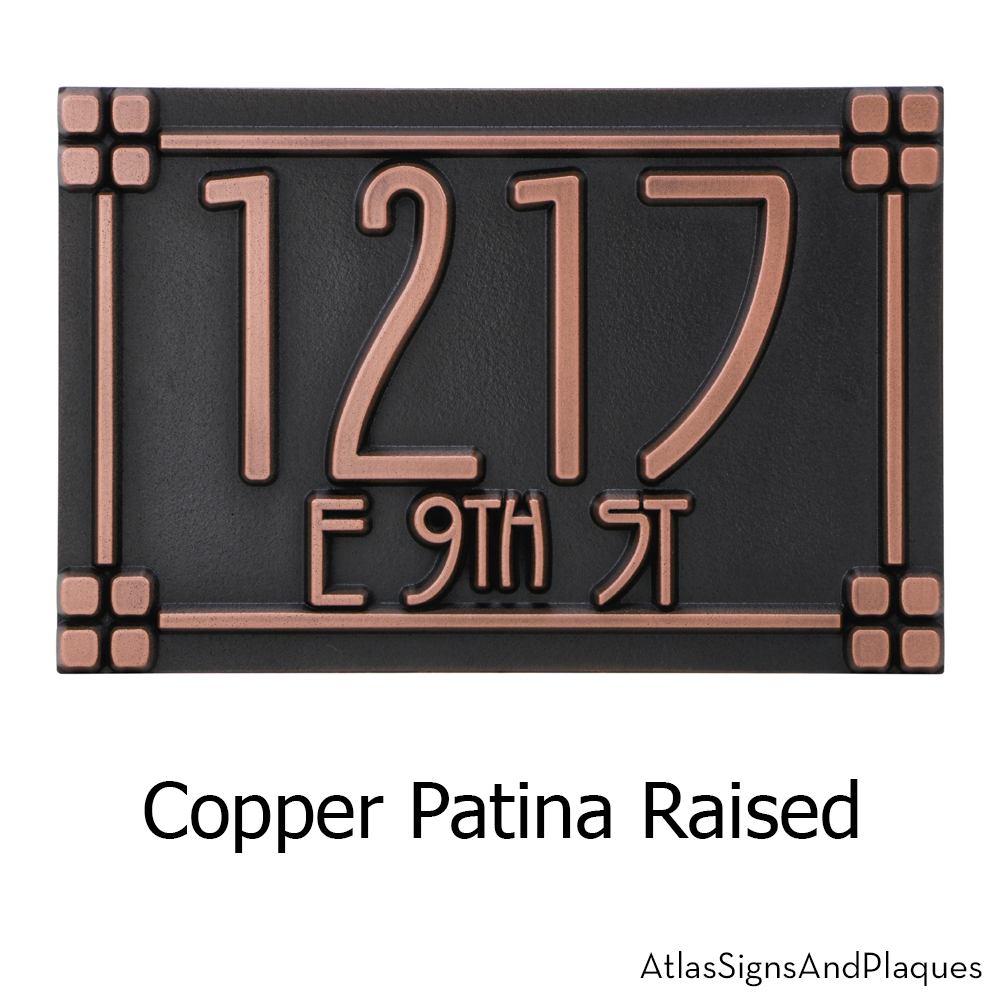

Readying and Applying Metal Patina Day 7: January 22, 2009. With the spray application of LuminOre® Bronze completed, the outer frame project is nearing the half-way point. The sprayed metal requires some time to cure and fully harden prior to the finishing steps. Despite the frigid temperatures, shop heat is left at 74 degrees overnight to aid the process. We can’t wait to see the gas bill for this month. During the cure process, the metal coating develops a bit of a sticky glaze on the outside which must be removed before patination and final finishing. Again, mostly hand work. We usually remove the glaze with a light abrasive blast, and this was no exception. Some of day 7 is spent sandblasting, but the remainder of our time is used to hand-tune the frame surface so we have a nice even metal base that will take the patina and give [...]