Clear Coating the Outer Frame & Begin Inner Frame

Packing in Process

Day 11: January 26, 2009. Clear coating day for the outer foam frame. The final step prior to packing and shipping. Each of the 24 pieces of the outer frame for the US Capitol Visitor Center display is carried to a rolling cart, placed on a special set of jigs that our crew constructed from four by four lumber, and rolled to the spray booth area. The super-premium clear-coat is mixed and poured into the spray gun.

Then, two coats applied to each piece, and cart moved to the drying area for curing. Although a practiced hand, and quality equipment are necessary to apply the top coat, this is a relatively easy step that does not require grueling hand-work . Best of all, it means that the piece is done and, after curing, ready to crate for shipment.

Cold Spray LuminOre® Bronze Application

The aluminum inner frame requires a different preparation treatment. Frame is made up of 40 pieces ranging from 2 feet to 12 feet in length and each needs to be abrasive blasted to clean the aluminum and provide a rougher surface to aid in adhesion of the metal. This process is known as profiling.

After blasting, human hands will never touch the surface until final clear coating. Pieces are grouped or taken singly to the spray booth for Bronze Coating using the patented LuminOre® process.

Day 12: After curing overnight in a very hot shop, each, now coated piece goes back to the abrasive area for a light blasting with fine crushed glass to remove the glaze and prepare the surface for patina. Patina chemicals applied and rinsed after the proper color obtained. Sounds easy, but a messy process with work going on into the night.

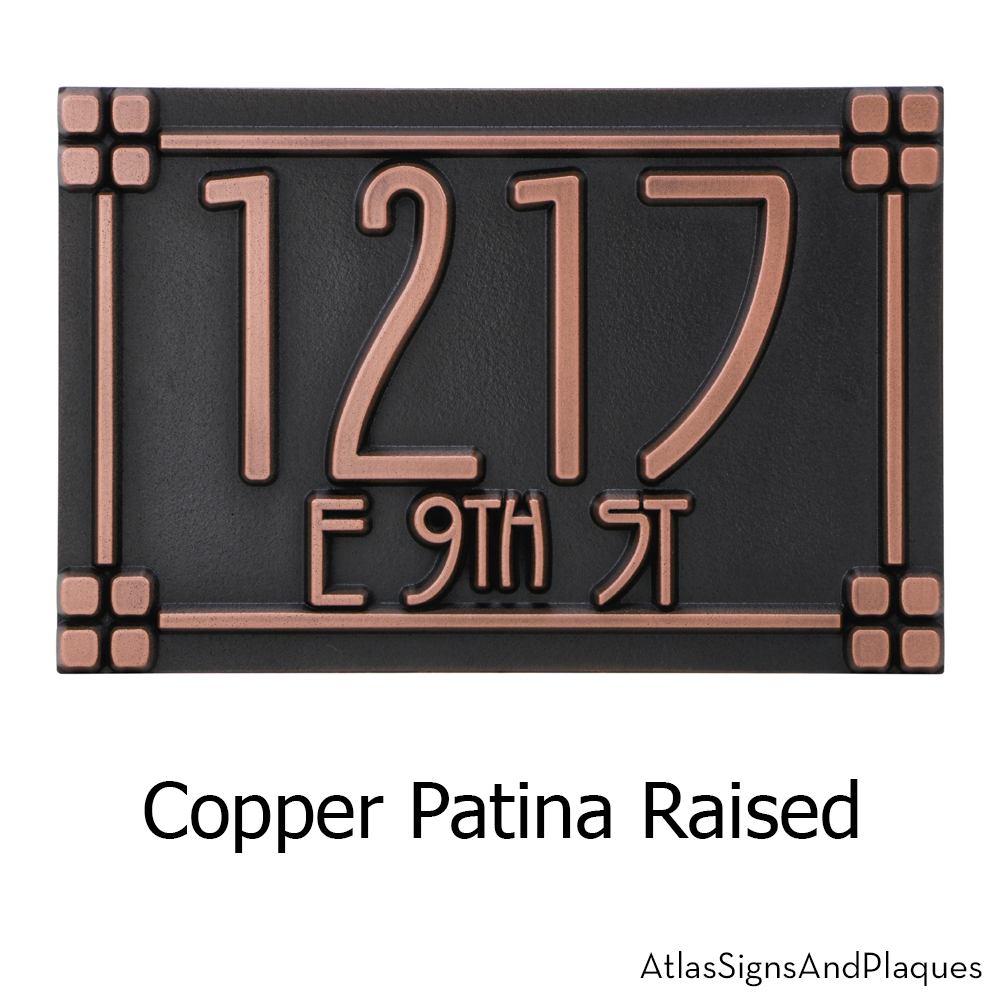

Inner Frame After Coating with Bronze and Patin

Day 13: Again each of the 40 pieces moved, in turn to the spray booth for clear coating. We are barely aware that every time we run the paint booth, our million BTU make-up air unit is burning gas at rate that makes the meter spin at a blurring speed. Our ultra-high-quality clearcoat drys fast in the warmth of the shop and the inner frame is ready to pack in just a few hours. Padding and packing into the night. The final screws are driven into the crate tops, and the cheap red wine is broken out.

Day 14: Job Completed! On Time, As Promised. Ready to ship back to Hadley Exhibits in Buffalo NY. Scheduled to be installed soon. We hope this blog series has given you a little insight into what goes into what you see, and will cause you to look closely at the frames when you visit. We are very proud to have been included. Ours is a very small part in this massive project and we completed it as a woman / veteran owned business (Atlas Signs and Plaques), using all USA materials and labor.